Risk Analysis and Modeling

SWL, with its expert team and advanced computer modeling software, predicts and simulates potential hazards in industrial facilities. By modeling the impact areas of events such as fire, explosion, and toxic spills, it empowers businesses to take preventative measures.

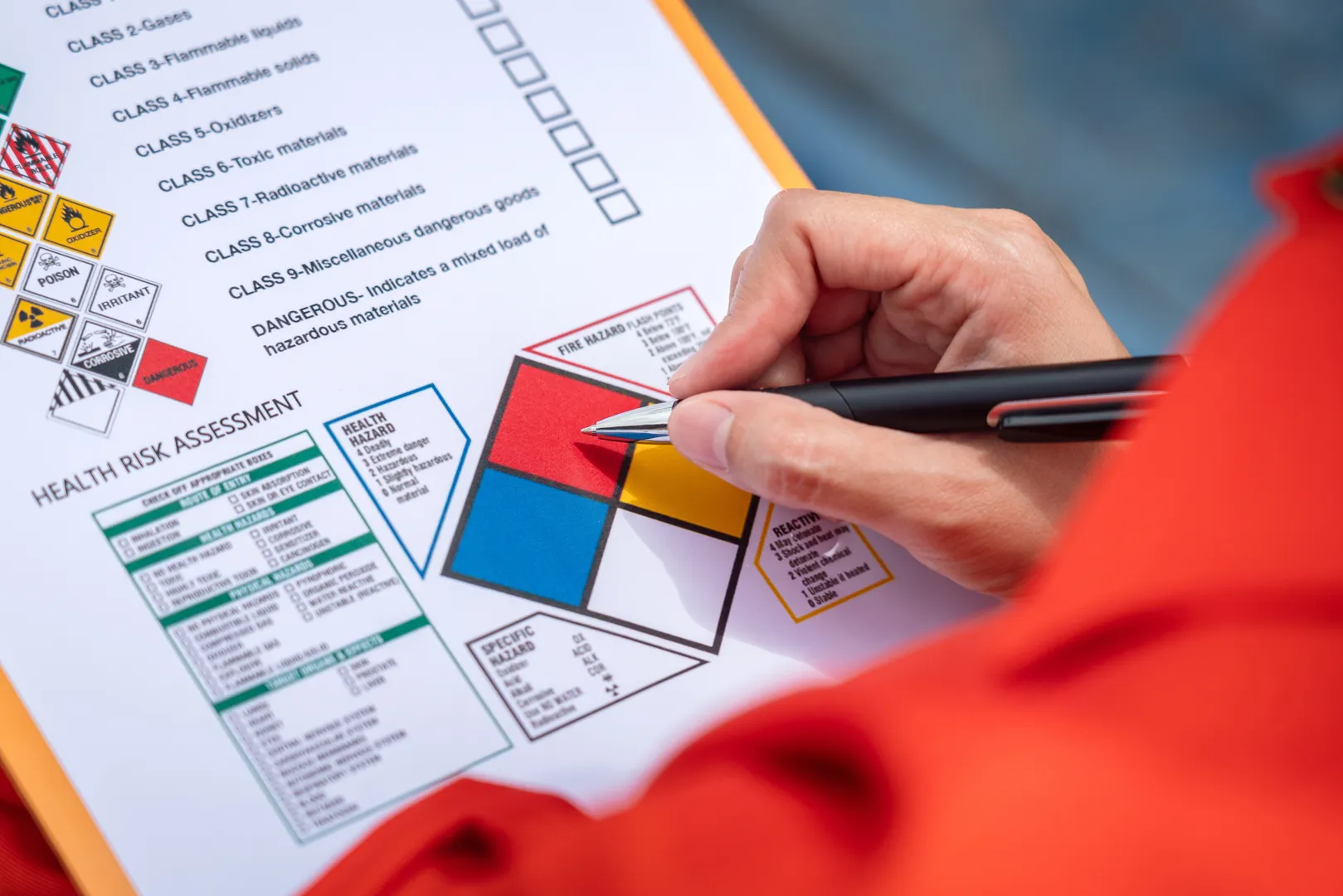

Risk Assessment and Management

Scaffolding-related accidents in industrial facilities account for 25% of all workplace accidents. Proper control and engineering solutions reduce this risk by 95%. SWL specializes in safe system design and management across all phases of the hydrogen industry, offering comprehensive engineering and consulting solutions with a team of technical experts experienced at every point in the hydrogen supply chain and throughout the entire facility lifecycle.

Our multi-dimensional risk assessment approach, integrating the requirements of Türkiye’s Occupational Health and Safety Law No. 6331, the German TRBS technical rules, and the British HSE guidelines, meets both local regulatory compliance and international best practices. With experience in petrochemical, energy, mining, manufacturing, and other industrial sectors, we identify your specific risk factors and control measures to help you establish a sustainable risk management framework.

With SWL’s risk assessment and management services, take a proactive approach to identify potential hazards early, optimize the effectiveness of risk mitigation measures, and increase operational resilience.

Our Risk Analysis and Modeling Services

Our comprehensive risk analysis and modeling services as SWL

Risk Analysis

SWL offers engineering-focused risk analysis services, specializing in systematically identifying, assessing, and managing potential hazards in industrial facilities. Our risk assessment approach, based on scientific methodologies and international standards, enables you to develop proactive strategies to enhance your business’s operational safety and ensure business continuity.

Engineering-Based Risk Analysis Methodology

Our risk analyses include systematically identifying hazards, quantitatively assessing risks using engineering calculations, and developing hierarchical control measures. Applying principles of physics, chemistry, electricity, and engineering, we scientifically evaluate risk factors and recommend technically feasible and cost-effective risk mitigation solutions.

SWL’s Integrated Risk Analysis Approach

- Structured Hazard Identification: Using systematic methodologies such as HAZID, HAZOP, and What-If, we comprehensively identify all potential hazard sources specific to your facility. By combining historical data, industry experience, and technical analytical approaches, we also uncover hidden hazards.

- Quantitative Risk Assessment:< 0 >We determine the probability and severity parameters quantitatively with engineering calculations and statistical analysis, prioritize them in risk matrices and evaluate their acceptability levels according to objective criteria.

- Multi-Layered Risk Reduction Strategies:< 0 >We develop multi-layered strategies that include technical, operational and organizational measures to control risks and offer solutions in accordance with the risk control hierarchy (elimination, substitution, engineering controls, administrative controls, PPE).

- Dynamic Monitoring and Continuous Improvement:< 0 >We regularly evaluate the effectiveness of risk analyses and control measures and support the continuous improvement of the risk management system in line with operational changes, technological developments and new regulations.

Proactively manage potential hazards at your facilities, minimize the risk of accidents and operational disruptions, ensure legal compliance, and build a sustainable safety culture with SWL’s comprehensive risk analysis services.

Fire Modeling

SWL provides scientific engineering services that simulate potential fire scenarios originating from combustible materials in industrial facilities, drawing on the principles of combustion physics, heat transfer, and fluid mechanics. Our sophisticated analytical approach, integrating thermal radiation models, computational fluid dynamics (CFD) software, and semi-empirical correlations, allows us to precisely characterize the behavior and potential impacts of different fire scenarios.

Our Scientific Approach to Fire Dynamics

Our modeling methodology, which takes into account the complex physical and chemical processes of fire, combines the principles of combustion chemistry, thermodynamics, turbulent flow, and heat transfer to scientifically describe the nature of industrial fires. By integrating multiple parameters such as fuel properties, weather conditions, geometric configuration, and combustion dynamics, we realistically simulate fire behavior and its effects, precisely identifying potential hazard zones.

Our Comprehensive Fire Analysis Services

- Hydrocarbon Pool Fire Modeling:< 0 >Mathematical modeling of burning rate, flame geometry and thermal radiation profiles of pool fires caused by liquid fuel spills, analysis of the effects of pool diameter, fuel type and environmental factors on fire behavior

- Pressurized Gas Jet Fire Simulation:< 0 >Calculation of flame length, width and thermal radiation characteristics of jet fires originating from gas under pressure or dual-phase leaks, modeling of momentum and heat transfer interactions, evaluation of the effect of different wind conditions

- Thermal Radiation Dosage Analysis:<0>Calculation of thermal radiation emitted from fire sources depending on distance, determination of safe distance criteria taking into account equipment endurance limits and human tolerance thresholds, mapping of radiation contours onto the facility layout.

- Structural Thermal Analysis:< 0 >Finite element analysis modeling of thermal response of structures and equipment exposed to fire, integrated simulation of heat transfer mechanisms (conduction, convection, radiation), evaluation of temporal effects on structural integrity

- Advanced Smoke Dispersion Modeling:< 0 >CFD-based modeling of the production and atmospheric distribution of combustion products and toxic gases, assessment of visibility restrictions and respiratory hazards, optimization of evacuation routes and identification of safe refuge areas

With SWL’s engineering-based fire modeling services, scientifically assess your facility’s fire risks, optimize your fire protection systems, and develop your emergency response plans based on hard data. Our analyses, which integrate physics and engineering principles, provide the scientific basis for decisions you make to protect your critical assets and personnel.

Explosion Modeling

SWL provides scientific engineering services that model explosion scenarios that can occur from flammable and explosive materials in industrial facilities based on thermodynamic principles, shock wave theory, and structural dynamics analysis. Our sophisticated analytical approach, which integrates advanced computational software, empirical correlations, and semi-empirical modeling, allows us to precisely characterize the physical behavior and potential effects of various explosion scenarios.

Our Engineering-Based Modeling Methodology

Our analysis approach, which takes into account the complex physics of explosions, combines the disciplines of combustion chemistry, gas dynamics, shock wave physics, and structural mechanics to scientifically explain the nature of industrial explosions. Using complementary methodologies such as TNT equivalence, multi-energy approach, and specialized simulations (CFD), we develop models tailored to different plant configurations and explosion scenarios, assessing explosion effects in three dimensions.

Our Comprehensive Explosion Analysis Services

- Flammable Vapor Cloud Explosion (VCE) Modeling:< 0 >Simulation of the explosion behavior of vapor clouds formed by flammable hydrocarbons and reactive gases, analysis of the effects of degree of compression, delay factors and ignition energy, characterization of different explosion regimes (deflagration/detonation)

- Container Explosions and BLEVE Analysis:<0>Modeling of sudden rupture of pressurized containers and boiling liquid expanding vapor explosions, integrated analysis of pressure wave, projectiles, and thermal radiation effects, assessment of domino effect potential

- Structural Response and Damage Analysis:< 0 >Modeling of dynamic response of buildings and equipment exposed to blast loads using finite element analysis (FEA), structural integrity assessment, prediction of structural damage with different damage criteria, durability analysis of critical equipment

- Human Impact Assessment: <0>Evaluation of the potential effects of the blast wave on humans using probit functions and biomechanical criteria, regional mapping of injury and death probabilities, determination of safe distance criteria.

- Explosion Resistance Optimization:< 0 >Evaluation of the effectiveness of explosion barriers, pressure relief systems and protective structures with numerical simulations, development of cost-effective explosion protection strategies, optimization of design parameters

With SWL’s advanced explosion modeling services, scientifically assess your facility’s explosion risks, optimize the explosion resistance of structures and equipment, and proactively ensure human and environmental safety. Our analyses, based on engineering and physics principles, support your technical decisions and assist you in regulatory compliance.

Toxic Release Modeling

SWL offers advanced engineering services that utilize scientific methodologies to analyze the atmospheric behavior and potential human health impacts of potential releases from hazardous chemicals in industrial facilities. Using Gaussian dispersion models, heavy gas dispersion algorithms, and specialized simulations, we characterize toxic clouds under various environmental conditions and precisely define their impact areas.

Our Scientific Modeling Approach

Our dispersion models, developed based on thermodynamic principles, atmospheric physics, and chemical kinetics, integrate physical and chemical properties of chemicals, release conditions, meteorological parameters, and topographic factors to create realistic dispersion scenarios. Using wind profiles, atmospheric stability classifications, and turbulence parameters based on weather station data, we simulate the behavior of toxic clouds under various weather conditions, accounting for uncertainty factors.

Our Comprehensive Toxic Distribution Analysis Services

- Source Term Modeling:< 0 >Characterization of leakage and release scenarios that may arise from storage tanks, process equipment and pipelines with thermodynamic calculations, liquid pool evaporation, two-phase flow dynamics and physical modeling of jet oscillation behavior

- 3D Dispersion Simulation: Using advanced software, three-dimensional simulations modeling toxic clouds around complex terrain, structures and obstacles, taking into account micro-meteorological effects and flow dynamics between buildings

- Toxicological Impact Assessment:< 0 >Dose-response analyses, potential health effects and scientifically based determination of control zones using AEGL (Emergency Guideline Levels), ERPG (Emergency Response Planning Guideline Values) and IDLH (Immediately Dangerous to Life and Health) toxicity criteria

- Temporal-Spatial Risk Analysis:< 0 >Analysis of the change of toxic concentrations depending on time and location, modeling the relationship between exposure time and concentration using probit functions, social risk assessment by integrating with population distribution

- Emergency Response Strategy Optimization:< 0 >Creating a scientific basis for evacuation zones, safe refuge areas and emergency response corridor design, warning systems layout optimization and decision support mechanisms based on modeling.

Scientifically assess chemical risks at your facility, optimize your emergency response plans, and proactively ensure public safety with SWL’s toxic release modeling services. Our engineering-based analyses help you meet regulatory requirements and fulfill your corporate social responsibility.

Nicel Risk Değerlendirmesi (QRA)

SWL offers Quantitative Risk Assessment (QRA) services, which utilize advanced engineering approaches to analyze potential hazards in industrial facilities using mathematical models and express risks using objective numerical parameters. Using probability theory and consequence modeling techniques, we ensure that your risk management strategies are based on objective, scientifically based decisions.

Our Scientific QRA Approach

Our QRA methodology combines deterministic and probabilistic analysis techniques to create a comprehensive picture of risk factors in complex industrial systems. Our multidimensional analysis approach, integrating statistical models, physical formulas, and engineering principles, enables quantitative characterization of risks and quantitative assessment of the effectiveness of risk mitigation measures.

Our Comprehensive QRA Services

- Advanced Scenario Analysis:< 0 >Systematic mapping and frequency analysis of potentially hazardous scenarios using fault tree and event tree methodologies

- Stochastic Modeling:< 0 >Modeling uncertainties and determining confidence intervals using Monte Carlo simulations and other probabilistic techniques

- Multiparameter Consequence Analysis:< 0 >Multi-faceted modeling of the physical effects of accident scenarios using thermodynamics, fluid mechanics and structural engineering principles

- Developing Integrated Risk Metrics:<0>Calculation of comprehensive risk indicators such as individual risk contours, F-N curves and potential loss life analyses

- Risk-Based Design Optimization:< 0 >Optimization of security systems design and operational procedures based on quantitative risk criteria

Our QRA services provide a scientific basis for your critical decision-making processes, such as risk assessment based on the ALARP (Lowest Reasonably Practicable Level), investment prioritization, cost-benefit analyses, and regulatory communications. Our advanced analytics approach helps ensure that uncertainties are addressed transparently and that your risk mitigation strategies are based on reliable data.

Fault Tree Analysis (FTA)

SWL offers comprehensive Fault Tree Analysis (FTA) services to analyze the root causes of system failures and accidents. FTA is a deductive analysis technique that visualizes potential failure modes and their interrelationships in complex systems.

Fault Tree Analysis Methodology

FTA creates a diagram that logically connects a system failure or undesirable event (top event) to root causes and underlying events. This structure uses AND and OR gates to show how underlying events combine and contribute to the system failure.

SWL’s FTA Services

- Qualitative FTA:<0>Structural analysis of system failures and determination of root causes

- Quantitative FTA:<0>Numerical calculation of the probability of the peak event

- Minimal Cut Set Analysis:<0>Determining the minimum combination of events that can lead to system failure

- Sensitivity Analysis:<0>Evaluation of the impact of key events on system reliability

- Evaluation of Risk Mitigation Measures:<0>Analysis of the effectiveness of potential improvements

Our FTA approach serves as an effective tool for designing safety-critical systems and improving the reliability of existing systems. By systematically identifying vulnerabilities in your industrial facilities, complex equipment, and safety systems, we help you develop proactive maintenance strategies and optimize operational reliability.

Event Tree Analysis (ETA)

SWL offers comprehensive Event Tree Analysis (ETA) services to assess the potential consequences and impacts of initiating events. ETA contributes to risk assessment processes by examining how an initiating event could lead to different outcomes.

Event Tree Analysis Methodology

ETA starts from an initial event and deductively examines different outcome paths based on the success or failure of safety systems or intervention factors. This approach allows for the assessment of the probability and severity of each outcome scenario.

SWL’s ETA Services

- Identifying Initiating Events:< 0 >Identifying initiating events that could create potential danger

- Analysis of Security Systems:< 0 >Evaluation of the effectiveness of security barriers and intervention factors

- Modeling Outcome Scenarios: Characterizing different outcome paths and end effects

- Probability Calculation:<0>Determining the probability of each outcome scenario occurring

- Risk Assessment:<0>Analysis and prioritization of risk levels of outcome scenarios

Our ETA methodology can be integrated with other analytical approaches, such as LOPA (Layered Protection Analysis) and FTA (Fault Tree Analysis), providing a more comprehensive and in-depth understanding of your facilities’ risk profile. Event tree analysis results provide valuable information to support your decision-making in critical areas such as emergency response planning, safety system design, and risk communication.

Benefits of Our Risk Analysis and Modeling Services

SWL offers comprehensive risk analysis and modeling services, providing numerous benefits for your business. Our expert team understands the unique risk requirements of industrial facilities and develops customized solutions for each business.